AGO Calforma -

the heat transformer

Bring your waste heat back to a usable temperature level without significant operating costs.

The AGO Calforma is a heat pump that is powered by waste heat.

- Do you continuously dissipate waste heat into the environment?

- Do your processes result in moist/warm exhaust air flows with a high energy content?

- Could you make good use of heat at a higher temperature for process heat supply or for preheating?

- Are compression heat pumps not worthwhile for you because the electricity/gas price ratio is too high?

Use your waste heat to power a heat transformer (absorption heat pump type II) for process heat generation.

Areas of Application

Heat transformers are absorption heat pumps which transform heat from a low to a higher temperature level and use the supplied heat as actuating energy.

- Heat recovery of warm and humid exhaust air from drying processes

- Heat recovery of hood exhaust air from paper machines or vacuum pumps

- Heat recovery from drying plaster

- Heat recovery in food drying

- Heat recovery from sugar crystallization

- Further cooling of the district heating return

- Further cooling of thermal water

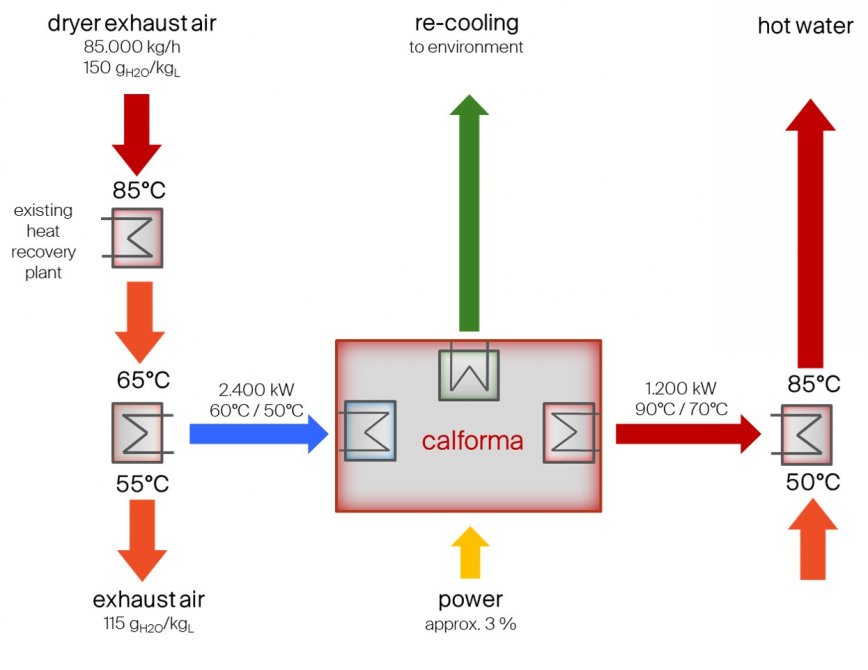

Application of an AGO Calforma

How AGO Calforma heat transformers work

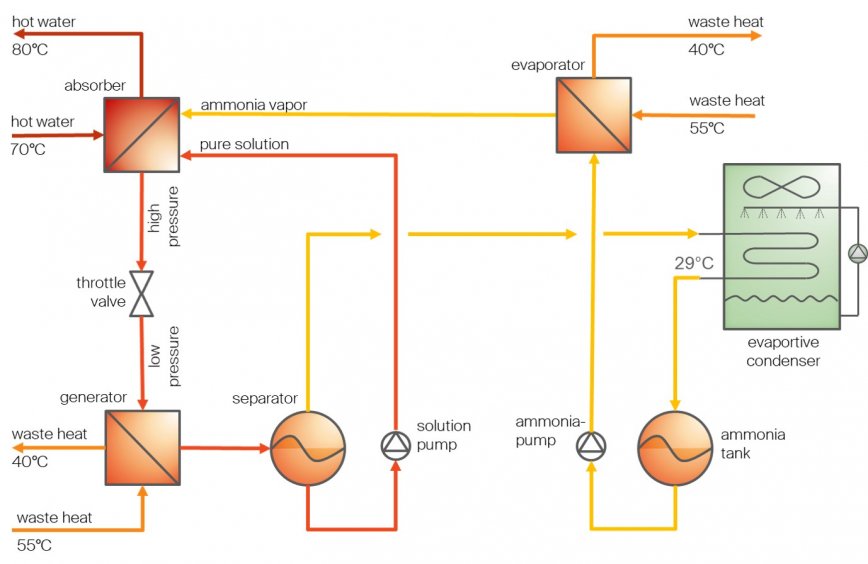

IIn the generator, vaporous ammonia evaporates out of the ammonia-rich solution being heated up by industrial waste heat. The poor solution that remains is pumped from the low pressure level to the high pressure level and preheated in an internal heat exchanger by means of heat recovery. The vaporous ammonia is condensed in a condenser, releasing heat into the environment. The liquid refrigerant is then also pumped from the low pressure level to the high pressure level and then evaporated in an evaporator by further supply of industrial waste heat. In the absorber, the vaporous ammonia dissolves in the poor solution. This is an exothermal process, which enables to heat up the usable heat cycle. The ammonia-rich solution is then cooled in the internal heat exchanger and throttled to the low pressure level by a throttle valve.

Technical data of AGO Calforma heat transformers

We manufacture AGO Calforma to suit your requirements:

- Temperature inlet heat: approx. 45°C to 70°C

- Temperature usable heat: 60°C to 110°C

- Capacity inlet heat: approx. 1,000 kW to 3,000 kW

- Usable heat load: approx. 400 kW to 1,500 kW

- Heat ratio (usable heat / inlet heat: approx. 0.35 – 0.5

- Electrical power demand including recooler: approx. 3 % of usable heat capacity

- Different recooling options: adiabatic cooler, hybrid cooler, evaporative cooling tower, evaporative condenser

- Installation options: indoor installation, outdoor installation, in a container

Advantages of AGO Calforma heat transformer

- Heat, which is usually available free of charge, is used as actuating energy

- Low maintenance and repair costs

- High-quality industrial design made of stainless steels

- Long service life, high reliability

- Uniquely high efficiency

- Use of natural refrigerants (GWP = 0; ODP = 0)

- No use of chemical additives (only pure ammonia and distilled water)

- Funding available

- Outdoor installation, indoor installation or in a container

- Stepless capacity control

Request data:

Your application is unique. The AGO Calforma is planned and manufactured precisely to match your application.

We need the following parameters for the design:

- available heat source load

- inlet and outlet temperature of the inlet heat

- inlet and outlet temperature of the usable heat

- climate condition, cooling water or condensing temperature

- type of installation (inside, outside, in a container)

Perhaps the AGO Calforma heat transformer is also a solution for your company?

We’ll happy to advise you!